2025 | Professional

Visual Multi-Level Control for Anhydrous Leather Dyeing

Entrant Company

Dongguan Milanna Leather Products Co., Ltd.-Shao Xiangdong

Category

Conceptual Design - Technology

Client's Name

Country / Region

China

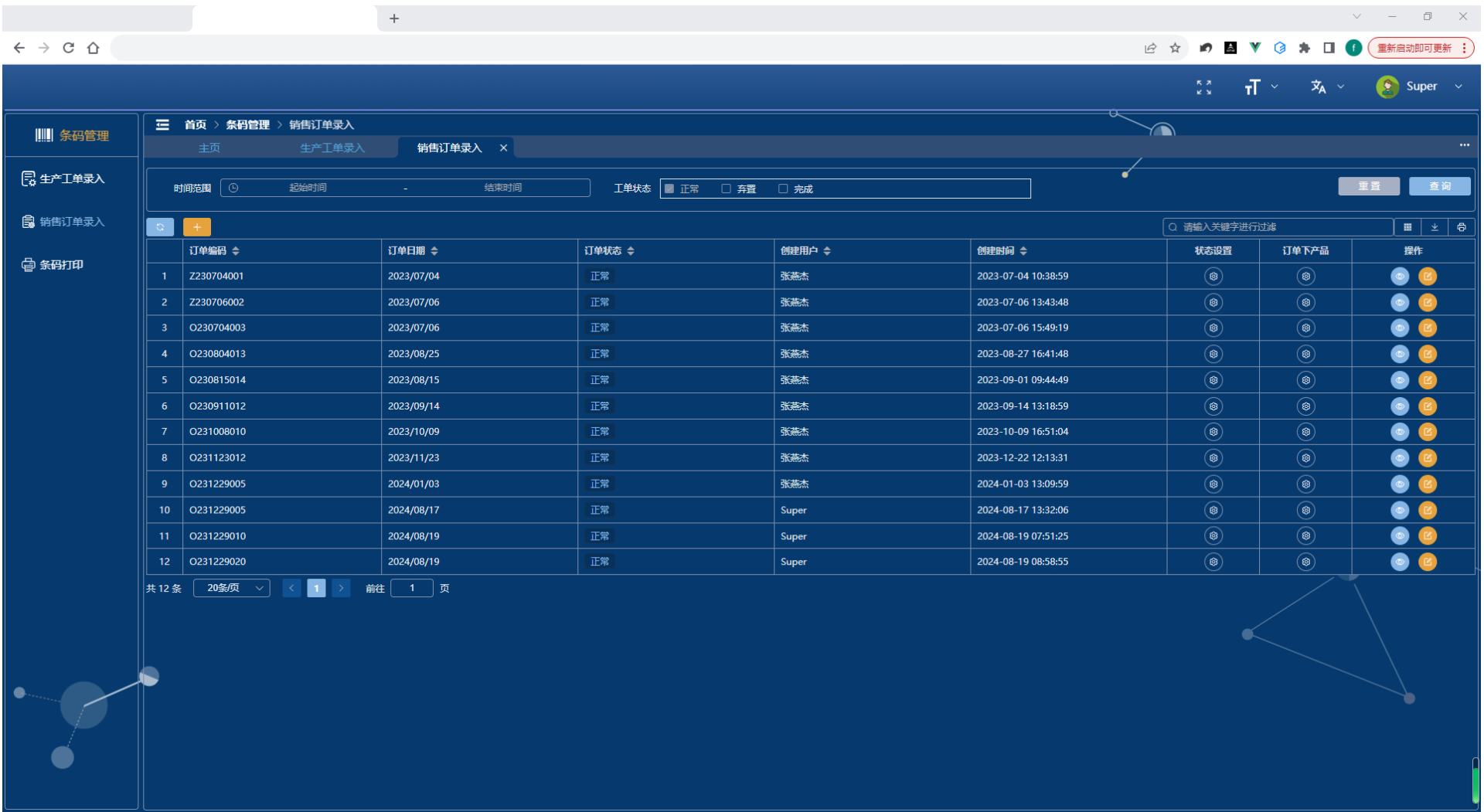

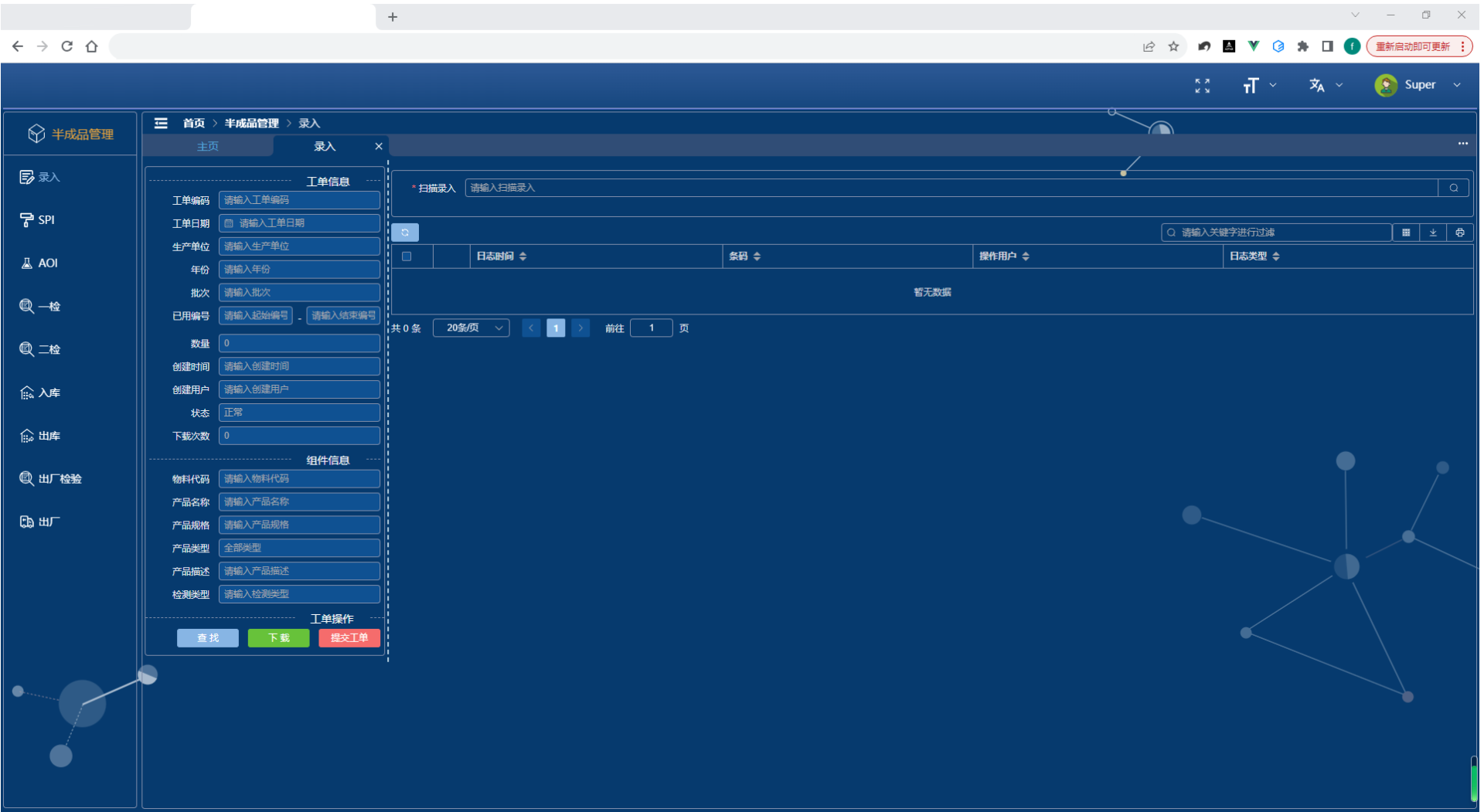

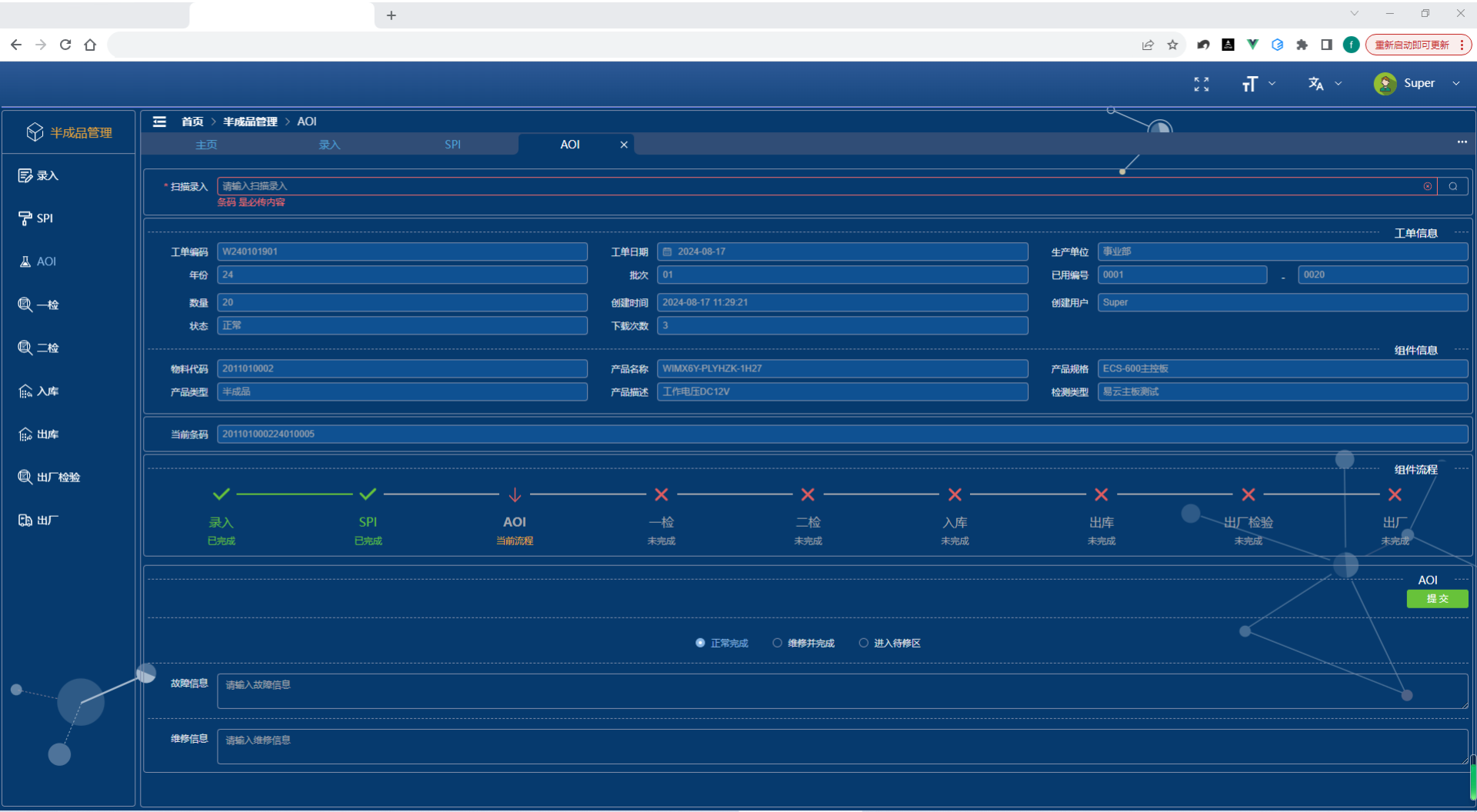

By integrating a high-resolution visual inspection module, a multi-level dyeing execution unit, a water-free circulation unit, and big data optimization algorithms, this system enables precision control over leather dyeing depth, color layer uniformity, dye liquor circulation rate, and dye consumption.

Leveraging a visual interface to display full-process data in real time, the system dynamically adjusts parameters through machine learning and adaptive algorithms. This not only ensures smooth color gradation transitions and strong color adhesion for leather but also achieves zero water resource consumption throughout the process—realizing automated and intelligent management of the dyeing workflow.

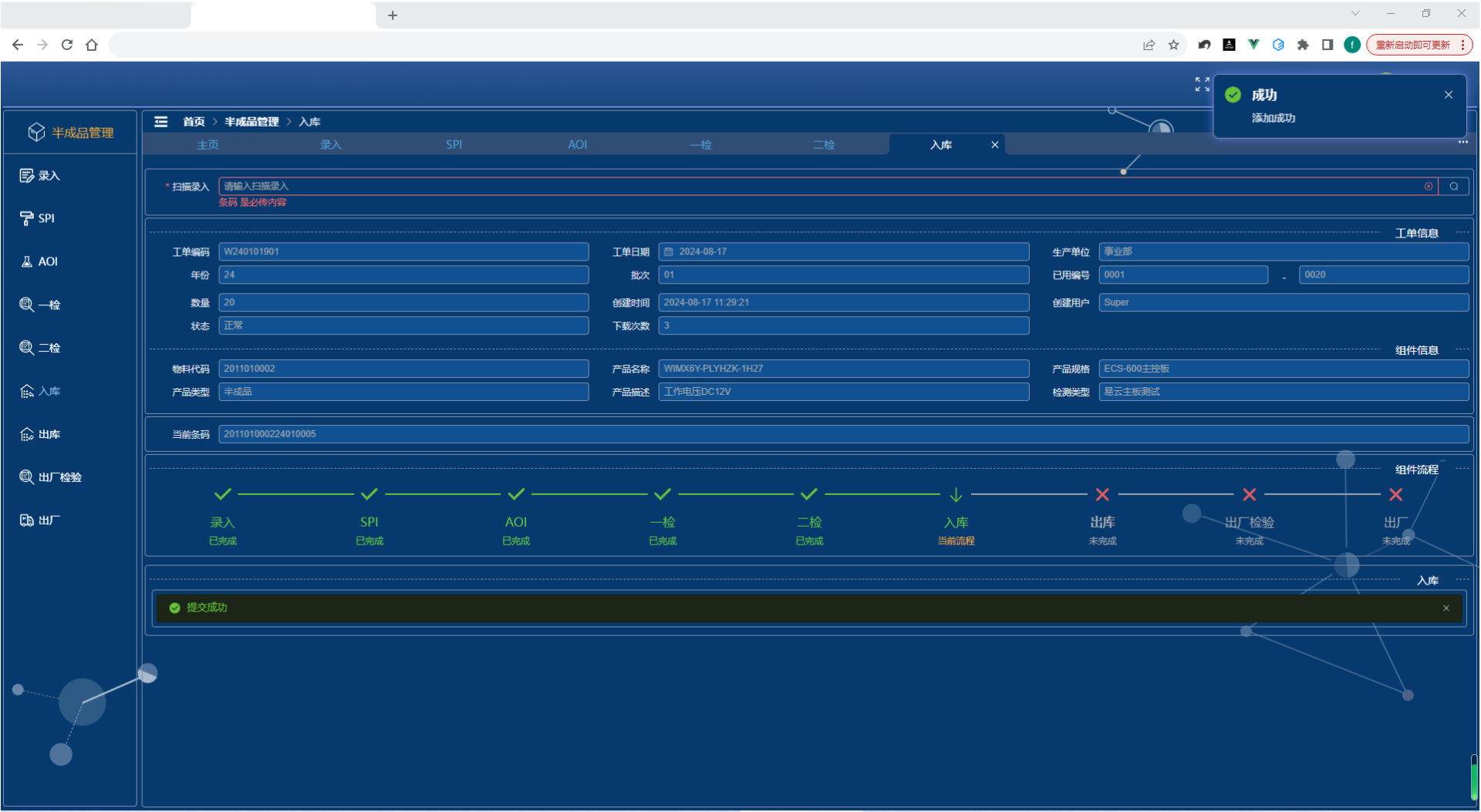

Meanwhile, the system prioritizes the dual optimization of environmental performance and color quality. Through its closed-loop dye liquor circulation design and control of low-volatility dyes, it not only achieves zero water consumption but also significantly improves dye utilization rate and markedly reduces VOC emissions. As a result, the residue levels of harmful substances in the leather are far below both national standards and international eco-leather standards, with its environmental performance meeting internationally advanced standards.

By contrast, the traditional leather dyeing industry is commonly plagued by pain points such as uneven coloration, difficulty controlling color layers, high water consumption (10–15 tons of water per ton of leather), and low dye utilization rates. This system, however, effectively addresses these challenges: it not only significantly narrows color layer deviation and achieves exceptionally high multi-layer color gradation matching accuracy but also boosts production efficiency, cuts dye consumption markedly, and eliminates the high wastewater treatment costs associated with traditional processes. In doing so, it truly delivers a win-win for both environmental and economic benefits.

After the application of this system, the defect rates of color difference and color fastness in leather products are significantly reduced. With zero wastewater discharge throughout the process, both environmental performance and quality stability are markedly enhanced. In terms of resource utilization rate, production efficiency, and product consistency, the system far outperforms traditional dyeing processes, establishing itself as a pioneering representative of technology in the field of automated water-free leather dyeing.

Credits

Entrant Company

Reunion Design Interior Decoration Co., Ltd.

Category

Interior Design - Home Décor

Entrant Company

Hengxiang Technology Co., Ltd

Category

Product Design - Robotics

Entrant Company

YI CIAO INTERIOR DESIGN

Category

Interior Design - Residential

Entrant Company

Yongkang Yu | Hunan Xiangsu Brand Design Co., Ltd.

Category

Conceptual Design - Mobile Life